Fabrication and Characterization of Zinc Oxide Nanorods

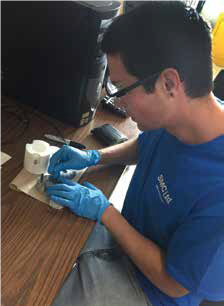

Zinc oxide (ZnO) is a wide bandgap semiconductor that has outstanding material properties. ZnO nanorods are advantageous because they can be used in various optoelectronic applications due to their extremely large surface area. The synthesis of these nanorods can be achieved through several different thin film deposition techniques. This spring semester, I worked on a project which used a process called electrochemical deposition (ECD) to create these nanorods on indium tin oxide (ITO) coated glass substrates. Such a process is cost-effective, easy to operate and scale up. After the fabrication process, I analyzed the dimensions and population density of the nanorods using a scanning electron microscope (SEM) in the Keck Microanalysis Laboratory and a UV-Vis spectrometer in the laser lab. The purpose of my research was to measure the change in the physical properties of zinc oxide nanorods caused by varying parameters, such as the molarity of the solution used, during the ECD process.

After graduation, I intend to gain employment at one of the local material science institutions here in Santa Rosa, whether that is in the field of thin film optics, like my research project, or in some other subcategory of that discipline.

Researchers: James Garner

Project Type: Capstone

Academic Year: 2019